FREE SHIPPING! This may not be in-store and we can drop ship it to you at no charge.

The Brewzilla (formerly RoboBrew) is an all-in-one electric brewing system that has built in elements for heating and boiling, a built in pump for recirculation, an onboard water resistant control panel for setting and monitoring temperatures, a removable grain basket, and a built in spigot for transfering. It is extremely portable and uses 110v power so it can be used nearly anywhere.

- WiFi / Bluetooth enabled RAPT Controller tracks your brewday and automatically uploads detailed information to the RAPT portal

- The top mounted RAPT Controller can be tilted upward for easy viewing, or detached from the unit to mount it on the wall or placed on your bench

- Mirror polished dome shaped bottom with center drain — get every last bit of wort into your fermenter while the perforated bottom screen filters out 95% of hot break and hop matter

- Make larger batches or higher gravity beers! BrewZilla offers the largest malt pipe capacity for units in its size range, and the Gen 4 unit has a 30% larger malt pipe compared to the previous generation

- Middle position feet allow you to lift out the malt pipe in two stages. Lift that heavy malt pipe to the middle position first, allow it to drain, then completely lift out the malt pipe for sparging

- Perforated bottom on the newly designed malt pipe allows for improved mash recirculation flow without sacrificing efficiency

- Element power percentage can be adjusted via the RAPT Controller. Go full power to heat up quickly, or dial it down so you don’t overshoot your strike water temp

- The built-in pump is plumbed to both the recirculation and arm and the bottom ball valve. Recirculate wort during your mash, then close the recirculation valve and pump wort to your fermenter via the bottom valve

- More RAPT-enabled accessories are coming including the Bluetooth Beacon Thermometer, and future firmware updates can be downloaded to the RAPT Controller itself over the internet

WiFi/Bluetooth Enabled RAPT Controller

The RAPT Controller is mounted to the top of the boiler body, allowing for easy operation when you have the unit set on the ground. The controller can be tilted upwards to give you an even better view, or it can be removed from the BrewZilla entirely if you’d prefer to mount the controller on your wall or lay it down on a workbench. From the controller, you’ll orchestrate your entire brew day. Program mash steps, dial in element power, and operate the integrated pump all from one screen.

But the RAPT Controller is much more than a beautiful, full-color display switch board. Once synced to the RAPT Portal, you’ll be able to track, record and monitor your brews online. No need for handwriting notes or punching brew day details into your phone – all of the data from your brew is automatically logged to your portal profile. This information doesn’t just include your mash profile; it also captures detailed information about your element power and pump activity, opening the door for very precise repeatability.

And the RAPT Portal isn’t just a digital archive for your brew days. With your BrewZilla powered on, you can control your brewery from virtually anywhere using your phone’s web browser. Not sure when you’ll be home from work or your kid’s ball game going into extra innings? No problem! Before you head out, simply log into the RAPT Portal from your phone and tell the BrewZilla to start heating your strike water. Along with remote control, the portal enables you to program alarms and push notifications for all of your boil additions. We’ve all been caught up with a side task and failed to throw in that yeast nutrient or clarifying agent at the end of the boil, but the BrewZilla has the back of even the most forgetful brewer!

But wait, there’s more! In addition to WiFi connectivity, the RAPT Controller is also a Bluetooth gateway device. KegLand is currently developing various Bluetooth devices such as the Bluetooth Beacon Thermometer and other sensors which will be compatible with your brewery upon release. The RAPT Controller is able to receive information from Bluetooth Low Energy (BLE) devices, adjusting its processes based on this new stream of information while simultaneously logging it to your RAPT Portal. With the Bluetooth Beacon Thermometer, for example, you’ll be able to feed temperature readings from the top of your mash bed to the controller. The controller will then compare this reading with the main temp probe reading at the base of the kettle and adjust element cycling based on these combined readings.

Finally, the RAPT Controller WiFi connectivity allows you to update the controller’s firmware with a single click. Take advantage of new features and accessories as soon as they become available by simply keeping your BrewZilla connected to your local WiFi network. And again, the WiFi is already built-in! No need to come back for an expensive add-on accessory down the road.

High Capacity Malt Pipe

With an approximately 23.5 lb capacity, the BrewZilla can mash nearly 50% more grain than similar sized models of the Anvil Foundry and Grainfather G30. If you want to fill your fermenter with more than a 5-gallon batch worth of wort, or brew the highest gravity beer recipes, the BrewZilla is the brewhouse for the job. And the included malt pipe is just the beginning. If you want to expand your brewery’s grain capacity even further, KegLand makes Boiler Extension Kits and Extended Malt Pipes for that very purpose.

Other features that we love on the BrewZilla malt pipe include the middle row of feet and perforated bottom. By adding a second row of feet to the malt pipe, you can remove it from the boiler in two stages. That first lift on the malt pipe when it’s full can be a heavy task, but with the middle row of feet you can do an initial lift, wait for the wort to drain, then lift it all the way out to completely drain the malt pipe and begin sparging. The malt pipe features a perforated section at the bottom which improves mash recirculation flow without sacrificing efficiency.

Concave Base with Center Draining

Leave no wort behind! The concave base with center drain means you’ll be able to extract every last drop of wort to your fermenter. If you’ve brewed in a traditional flat bottom kettle, this center drain may be a bit perplexing at first. Many brewers are used to whirlpooling after the boil to pull hop matter into the center of the kettle, then transfer out using a pick-up tube that pulls from the kettle wall in order to avoid sucking up the solids. But fear not! One of the key features of the BrewZilla is the false bottom protection screen. This screen avoids the need for doing a whirlpool, filtering wort as it transfers and blocking more than 95% of hops and hot break from getting sucked into the pump. This not only prevents blocked pump issues, it also increases the efficiency of your brewhouse by eliminating kettle loss from wort that may have otherwise been left behind.

Ultra Low Watt Density Elements

The concave base on the BrewZilla also allowed for larger heating elements with significantly lower watt density than other breweries. When a lot of energy is coming off of a small element, the local temperature near the element can be so high that it scorches the wort and causes caramelization. Lower watt density essentially means you can produce lighter color beers that would otherwise have fallen victim to caramelization effect. It also reduces that chance of boilovers and reduces stress on the elements which extends their life expectancy.

Easy Access Built-In Pump

The built-in pump allows you to recirculate your wort during the mash for improved efficiency and more even temperature distribution. But it can also be used to transfer your wort from kettle to fermenter rather than relying on a gravity feed, and with the optional CIP Rotar, you can used the pump to clean your BrewZilla (or fermenter) after every use. During your brew day you’ll be able to control the pump from the RAPT Controller with a dedicated button for turning the pump on and off. Another feature you’ll find on the controller is adjusting the pump flow. This doesn’t control the actual volume of the flow (you can do that from the ball valve located on the recirculation arm), but rather cycles the pump on and off automatically based on your setting. At 100%, the pump remains on continuously. But at 80%, the pump will cycle to be on 80% of the time and off 20% of the time. This may not be a feature that every brewer thinks they need, but it’s an excellent way to avoid running the pump dry accidentally, as the time the pump is off allows recirculating wort to filter through the grain bed and back into the pump inlet.

If you flip over the boiler, you’ll find the magnetic drive pump and all the plumbing is right at your fingertips. This means you don’t have to disassemble the base in order to access the pump for cleaning or maintenance if required. It also means the plumbing can be changed more easily too. For instance, the unit comes as standard with the plumbing from the pump feeding both the recirculation arm and the transfer valve, but you change this so the tap outlet bypasses the pump if you prefer.

Perfect for Distillation

If you want to expand your lineup of homemade libations to offer Spirits in addition to Ales & Lagers, the BrewZilla makes an excellent pot still! Add the Distillation Lid upgrade and pair it with an AlcoEngine Copper Reflux Condenser or Copper Pot Still Top. AlcoEngine Stills have been selling on the home market for years and offer some of the most affordable, beginner-friendly stills you'll find.

Features:

- Gen 4.0

- Stainless steel construction

- 9 gallon total capacity with a finished beer output of 5-6 gallons

- WiFi/Bluetooth Enabled RAPT digital temperature controller

- Automatic step mashing with 6 programmable stages

- 110V power and plug

- Dual heating elements (1000 watts and 500 watts)

- Stainless steel 1/2 inch ball valve for gravity draining or transferring via pump

- Immersion wort chiller included

- Stainless steel malt pipe/basket

- Stamped in volume markers

- Glass lid

- Magnetic drive pump for recirculation, transfers, and cleaning

- Recirculation arm

- Bottom handle for easy lifting and pouring

- Rubber feet

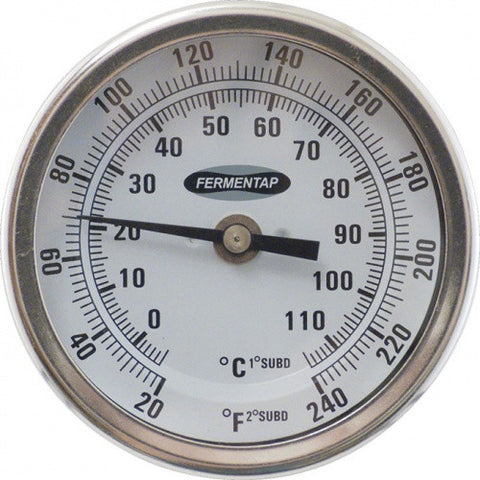

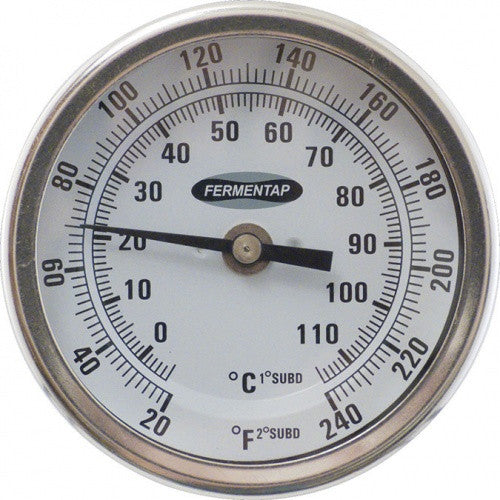

- Temperature reads in °F or °C

- 32.75 in H (with recirculation arm) x 12.5 in D

- Recommended max. grain bill - 23.5 lbs

- AlcoEngine Still ready with the purchase of a Distillation Lid

Pump Specs:

- Max Capacity: 2.9–3.1 gal/min

- Max Head: 4.9–6.8 ft.

- Poles: 2

- Voltage: 110–120V-AC

- Frequency: 50–60Hz

- Power: 6 watts

- Current: 60 mA

- Speed: 2600–3000rpm

- Duty Cycle: Continuous

- Capacitor: 2µF

- Input/Output: 13mm barb

- Water Resistance: IPX2

You Will Need:

- 2' of H985 1/2" ID Silicone tubing for sparging and draining.

- To connect included Chiller: (20') of 1/2" ID beverage tubing (or whatever length required, (3) hose clamps and (1) brass hose by thread adaptor.